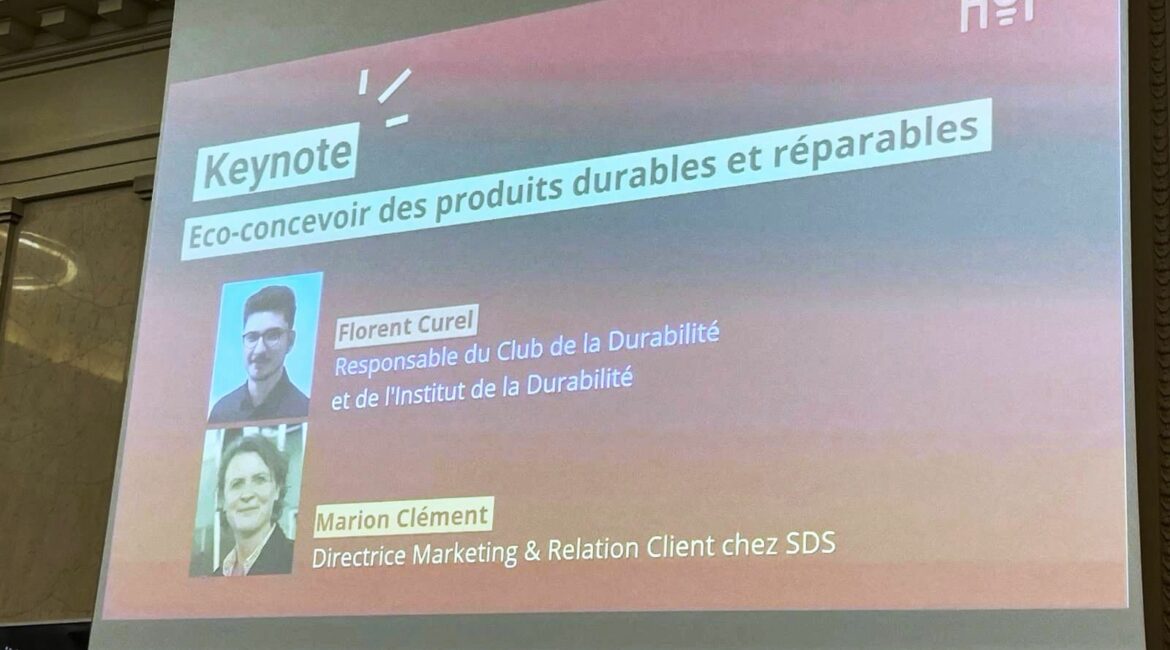

Marion Clément, our Marketing Director, participated in a symposium organized by the association HOP – Stop Planned Obsolescence, on February 9, 2024, at the National Assembly. This was an opportunity to present the new guide “Eco-designing Sustainable and Repairable Products” and to discuss the obstacles and progress of sustainability and repairability in France.

SDS recently participated in the symposium “Innovations in the Right to Sustainability” at the National Assembly. What was its objective?

The symposium was organized by the association HOP // Stop Planned Obsolescence, with whom we have been collaborating for a long time. Its aim was to bring together stakeholders from various backgrounds to exchange ideas and raise awareness about the challenges of sustainability and repairability in our society. We were fortunate to see all sustainability stakeholders present: representatives from circular economy companies such as ENVIE, members of public and associative organizations, eco-organizations, and several parliamentarians who attended the event. Even our Minister of Ecological Transition was supposed to be present; however, the ministerial reshuffle on the eve affected his schedule. This reflects the growing importance of these topics!

You presented during a conference with Florent Curel, Head of the Sustainability Club, the guide “Eco-designing durable and repairable products.” Could you tell us more about this guide?

MC: This guide is the result of a collaboration among several members of the Sustainability Club, a think tank of which we are part. Its main objective is to formalize the current challenges in the field of eco-design, while offering advice and best practices for businesses and the government. The ultimate goal is to promote the development of durable and repairable products. It addresses issues such as production and supply constraints, as well as challenges related to the costs of eco-design and repairability.

Indeed, let’s talk about these obstacles that you mention. What, in your opinion, are the main barriers to eco-design and product reparability?

MC: We identify two major barriers. The first concerns production and supply constraints. Currently, our value chains are often based on mass consumption and the pursuit of ever lower production costs. This often leads to products that are difficult to repair because they are designed to be assembled quickly and at a lower cost, without necessarily taking into account their durability or repairability.

The second barrier is the cost associated with eco-design and repairability. There is a feeling among many stakeholders that investing in these areas means starting from scratch, which can be discouraging. Moreover, the costs of training, research and development, as well as the costs related to the availability of spare parts for repair, can deter some companies.

You have, however, identified good practices and promising measures implemented in various sectors. Could you give us some examples of these initiatives?

MC: We are indeed seeing encouraging advancements! For example, the simplification of certain manufacturing processes to make devices more repairable at the component level. Another example is the use of interoperable electronic cards, which not only make repairs easier but also reduce manufacturing costs and increase profitability for producers of WEEE. Additionally, training engineers in eco-design and establishing new training programs for repair technicians to extend the lifespan of devices are positive steps. Some government measures, such as the introduction of repairability and durability indices, also represent significant strides towards more sustainable consumption models. The repair fund, a significant advancement to encourage individuals to repair items, has recently been subject to new measures to make it more appealing for both repairers and consumers. However, there is still work to be done, particularly in communication, to drive structural changes regarding this fund and the Qualirepar certification.

What actions is SDS taking at its level to contribute to this?

MC: On our end, we are working tirelessly to provide as many spare parts as possible. We continuously enrich our database of parts and appliances (over 100 million use cases). Our teams identify and stock important parts, which are constantly evolving with the launch of new appliance ranges by brands. Our goal is to enable repair professionals to easily find the right part and deliver them as quickly as possible. SDS Market (our marketplace), launched 2 years ago, is indeed a major complementary service for our repair professional customers. It helps address the unavailability of certain parts through the circular economy lever, thanks to our repair professional customers or large organizations like Envie. They reintroduce into circulation parts that are no longer available from brands or are too rarely requested for repairs: unused parts found in stocks or from second-hand appliances.

What would you say are the roles and challenges of public policymakers in further promoting eco-design and repairability of products?

MC: Public policymakers have a crucial role to play in this area. They can raise consumer awareness by making transparency about products placed on the market mandatory, and by expanding repairability and durability indices to other devices. Additionally, they can encourage businesses to adopt more sustainable practices by implementing tax incentives or binding regulations, such as the obligation to freely disseminate all documents related to devices (exploded views, spare parts lists, fault codes, repair tutorials, etc.). Finally, they can support research and development in this field, raise awareness among young people starting from school, and provide training for industry stakeholders.